Liquid HandlerALCS-2000custom

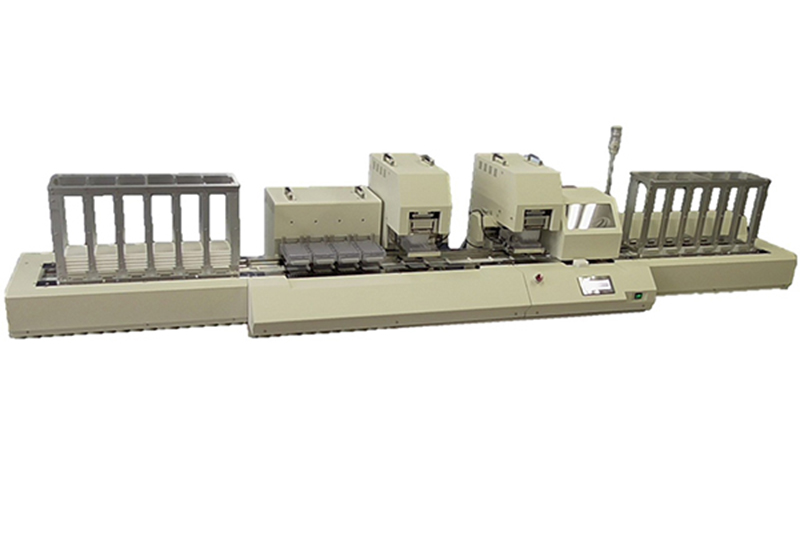

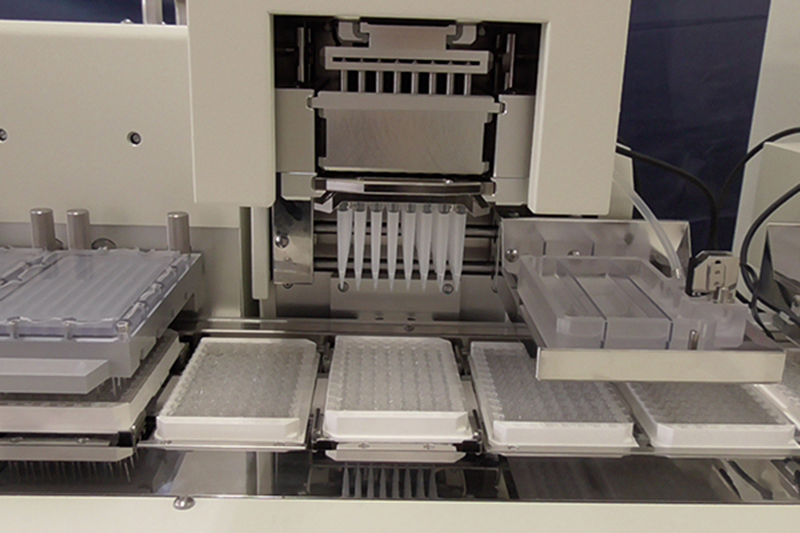

- 96-well continuous automatic dispensing and washing device for ELISA High-speed multi-dispense washer

- Please contact us

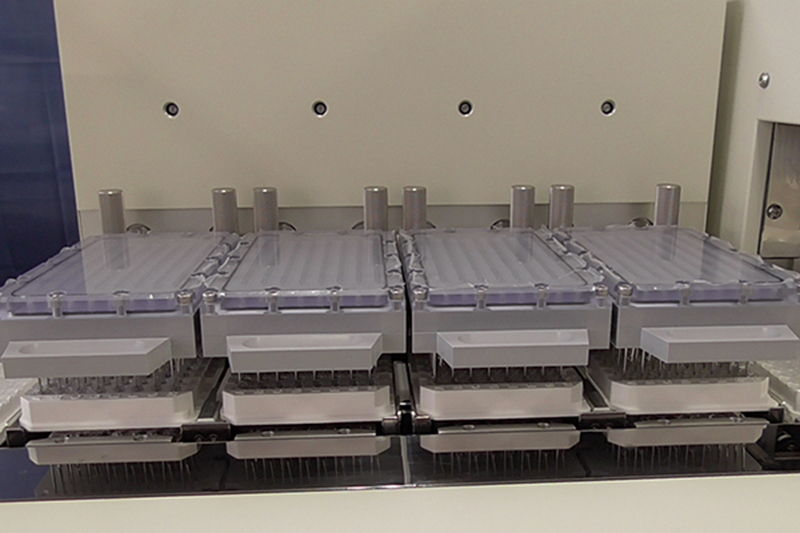

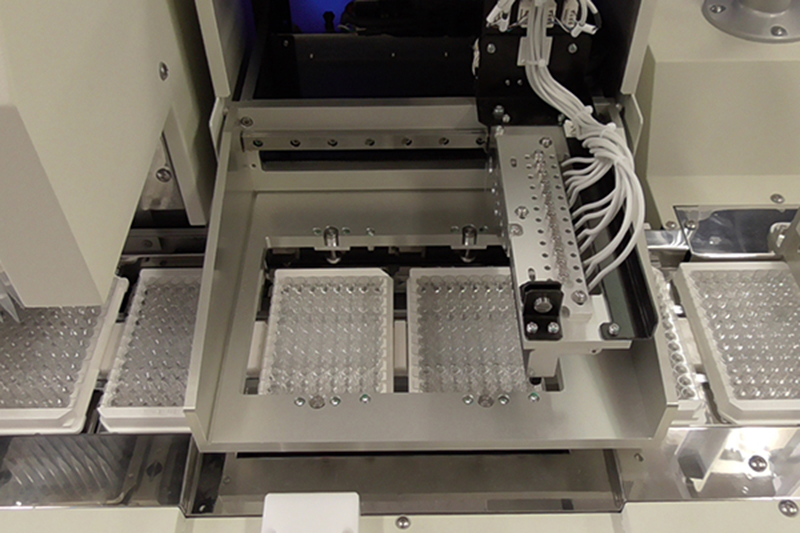

2 dispensing units

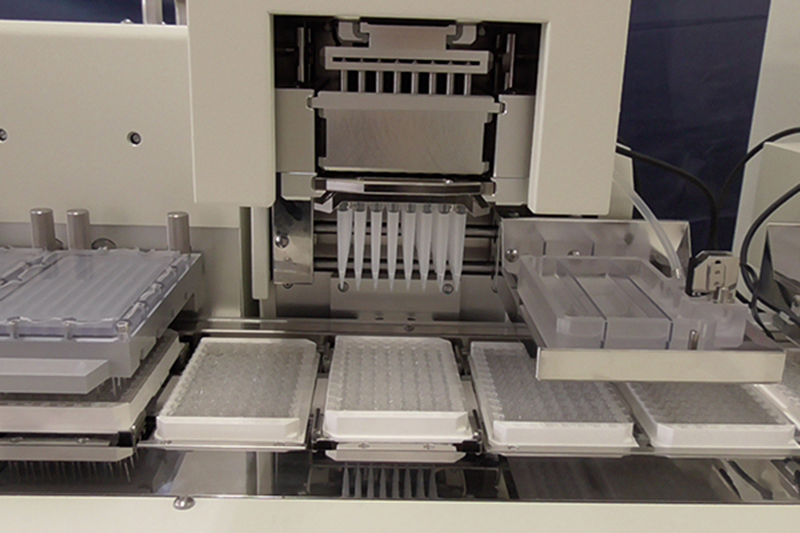

- It can fully automate a wide range of costly and laborious tasks, including dispensing antigens and antibodies, dispensing blocking solution, washing after coating, and ELISA assays, in the coating of EIA reagents on microplates.

- Dispensing antigens and antibodies on microplates, and washing and suction after coating can be performed quickly with simple operations, high reliability, and excellent reproducibility.

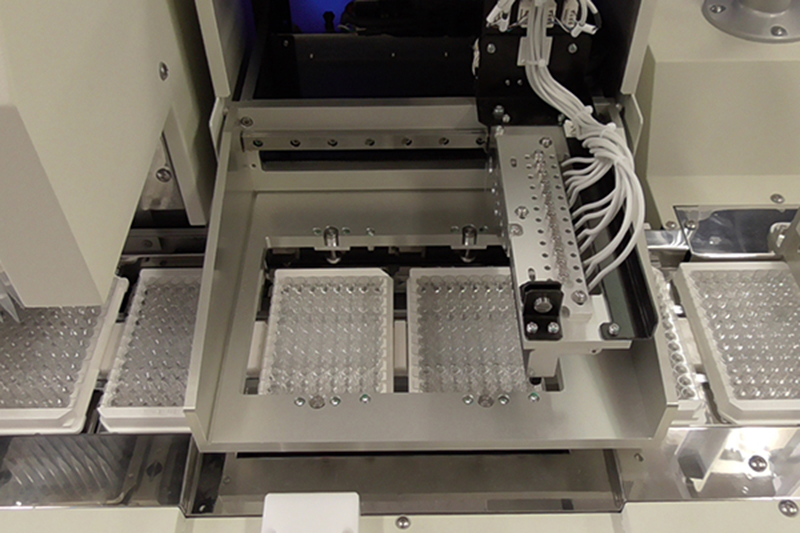

- The workstation can be combined with a washing unit, dispensing unit, and a newly developed dispensing confirmation unit according to the purpose.

(Please consult us about the number of each unit to be installed.) - The dispensing unit and washing unit can be easily set and removed.

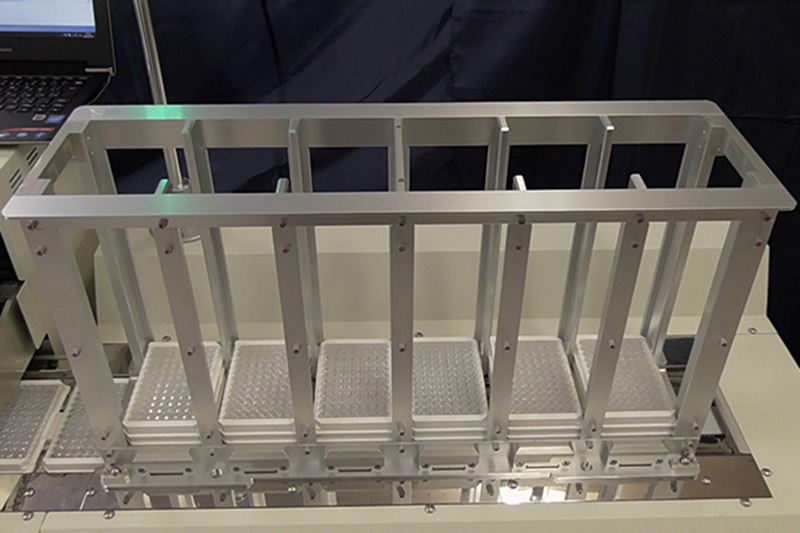

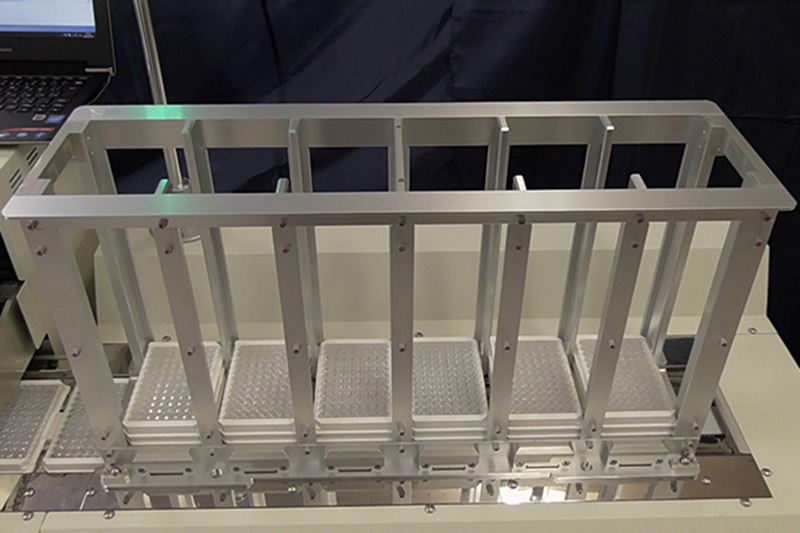

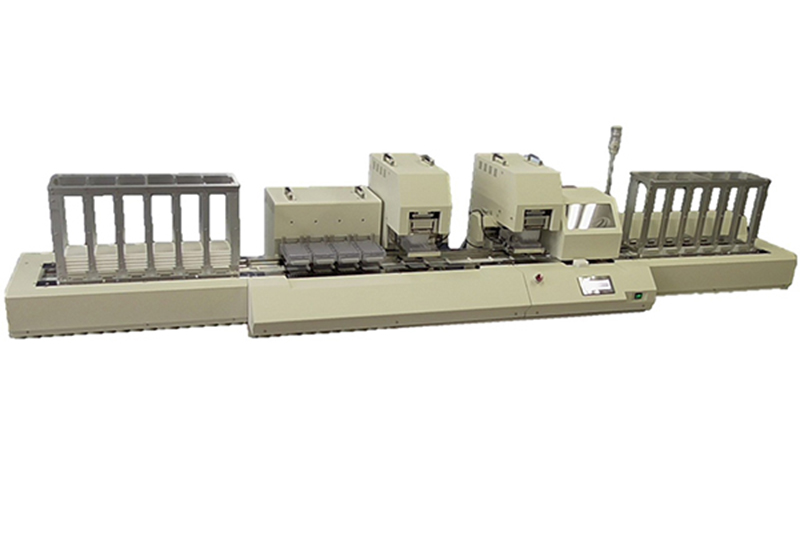

- The plate rack can hold 120 96-well microplates. Plates are automatically supplied and stored in groups of 6.

- The operation panel uses an easy-to-read LED panel with backlight.

Key Specifications

Main unit

| Dimensions | W2700mm×D912mm×H200mm (including stand/standard specifications) |

|---|---|

| Power supply | AC100V 50/60Hz |

| Control | 16-bit CPU control |

| Weight | Main unit About 200 kg |

Plate transport section and plate rack section

| Transportation method | Belt conveyor type |

|---|---|

| Plate detection | With plate presence/absence sensor |

| Number of plates that can be stored | Supply and storage 20 plates x 6 rows = 120 plates |

Dispensing unit

| Dispensing head | 96ch disposable tip type head 96ch stainless steel nozzle head |

|---|---|

| Dispensing method | 96ch independent cylinder method |

| Dispensing volume | 10 – 400 μL |

| Dispensing precision | CV2.0% or less(At the time of dispensing of 100 μL) |

| Dispensing mode | Contact and non-contact Small-portion and continuous dispensing |

| Compatible plates | Various 96 micro-well plates |

Washing unit

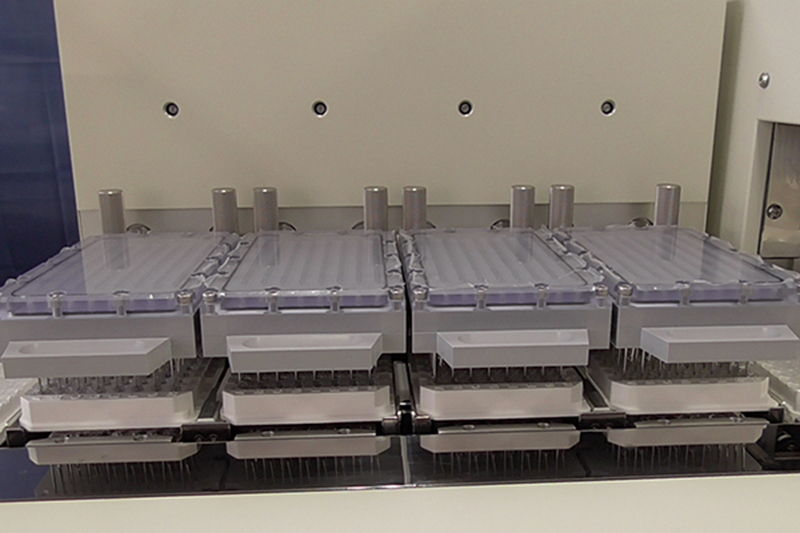

| Washing head | 96ch double nozzle head |

|---|---|

| Washing method | 96-well simultaneous washing |

| Washing solution dispensed amount | 50-800µL/well |

| Aspiration capacity | Residual solution amount after aspiration 1.5µL/well or less |

| Number of washes | 0-9 |

| Washing mode | Normal, Dispense, Aspirate, Dispense_end |

Dispense confirmation unit

| Detection method | Confirmation of dispensed amount in all wells by ultrasonic sensor (non-contact) |

|---|---|

| Processing capacity | 720 sheets/h (dispense confirmation operation only) |

Product introduction video

- ALCS 2000 Custom(3:06 minutes explanation)

Frequently Asked Questions

- What is the processing capacity?

- Example 1: 300µL x 3 washes + 250µL dispense + ultrasonic dispensing confirmation: 200 sheets/h or more (varies depending on conditions) Example 2: 1 200µL wash: 350 sheets/h or more (varies depending on conditions)

- What types of units can be set?

- Plate washing unit, plate vacuum unit, dispensing unit, dispensing confirmation sensor unit

- What is a plate vacuum unit?

- This unit automatically cleans (suctions) all wells of a microplate. Microplates taken out of the box often have dirt in the wells, so this unit is used to remove that.

- What plates are applicable?

- General 96-well microplates.

- Is traceability supported?

- By using the dispensing confirmation unit, you can check whether the specified amount has been dispensed into the well and leave a log. The log can be output in CSV format, etc.

Choose by product type

Choose from specifications

-

- Head Channel

- single/columns

- multi

- variable pitch

-

- Dispensing range

- low-volume

- middle-volume

- high-volume

-

- Price range

- ~¥5,000,000

- ¥5,000,000~

- ¥10,000,000~