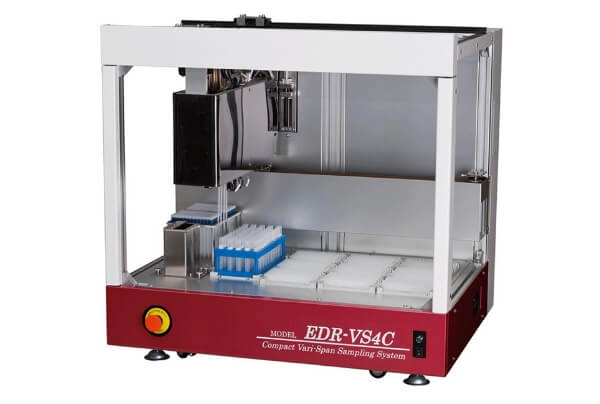

EDR-VS4C|Pipetting System

Pipetting System EDR-VS4C

Compact Variable Pitch Sampling Pipetting System

Specimen sampling/Reagent dispensing

- A compact model of the EDR-VS series, variable pitch sampling and pipetting system.

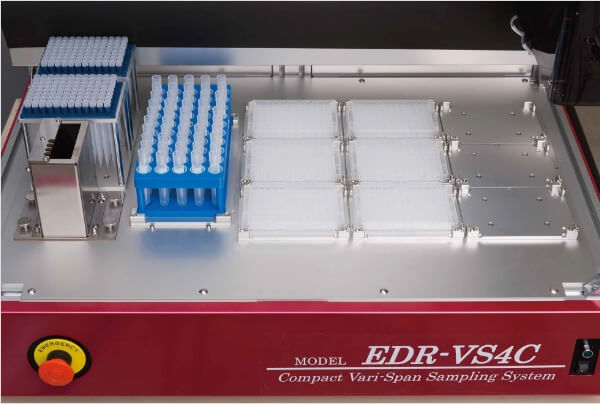

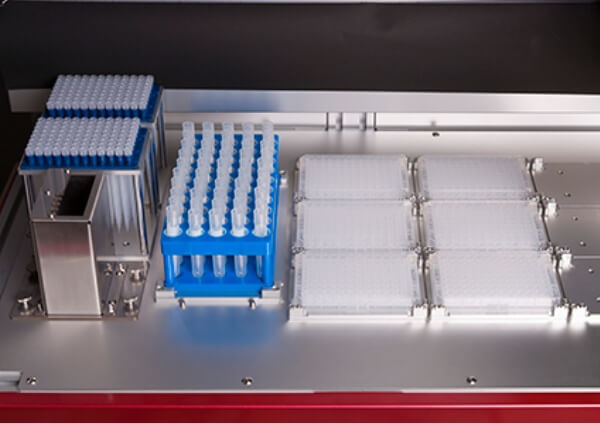

- The main body with dimensions of W 800 x D 650 x H 790mm provides a work area that can accommodate 15 micro-well plates.

- This model is suitable for sampling to 96 micro-well plates from centrifuge tubes, blood collection tubes and various other types of tubes.

- Sensing functions to for liquid level detection, tip mounting check, suction check, etc. are provided as standard.

- This model is capable of handling various multi-dishes, microtubes, etc. as well as 96 and 384 plates.

- Easily operated user interfaces that meet the needs of operators are employed.

- Dispensing operation is reproducible at a rate of 500 shots per hour.

Areas to Which the System Has Been Applied

Cells

Clinical testing

Food inspection

Diagnostic reagent manufacturing

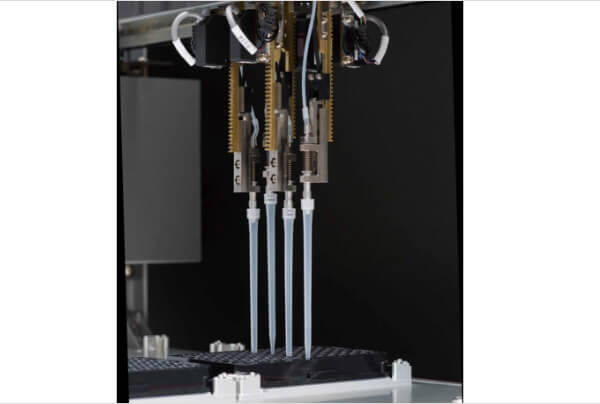

| Dispensing system | 4-ch independent cylinder system |

|---|---|

| Dispensing volume | 10 - 1000 µL |

| Dispensing precision | CV 3% or less (when dispensing 100 μL) |

| Compatible plates | Various 96 micro-well plates, deep well plates, PCR plates 1.5 mL/2.0 mL microtubes, blood collection tubes, centrifuge tubes, etc. |

| Dispensing precision | CV 3.0% or less (At the time of contact dispensing of 10 μL) |

| Dispensing speed | 500 shots per hour |

| Pitch variable range | 9~25mm |

| Power supply | AC100V 50/60Hz |

| Control | Dedicated PC software |

| Dimensions | W800mm×D650mm×H790mm |

| Weight | about 65 kg |

Watch YouTube videos in Chrome or Firefox.

Watch YouTube videos in Chrome or Firefox.

QWhat is the processing capacity?

A500 samples per hour.

(At a sampling speed without liquid level detection where tips are exchanged every time.The rate varies depending on dispensing conditions.)

(At a sampling speed without liquid level detection where tips are exchanged every time.The rate varies depending on dispensing conditions.)

QAre covers available?

AThey are available as options.You can select covers (with or without) HEPA filters.

QWhat types of errors are detected?

AErrors are issued when any of the following are detected during suction operation.

(1) Complete idle suction (When there is no liquid from the beginning), (2) Half idle suction (When there is a shortage of liquid), (3) Clogging detection (When the tips are clogged),

Other cases such as where there are no tips, and cases where jamming (a collision) occurs.

(1) Complete idle suction (When there is no liquid from the beginning), (2) Half idle suction (When there is a shortage of liquid), (3) Clogging detection (When the tips are clogged),

Other cases such as where there are no tips, and cases where jamming (a collision) occurs.

QHow are errors during suction detected?

AA pressure detection system is used.Carbon tips are not used.

QShould a dedicated PC be used?

AThe PC influences the processing speed, so please use a dedicated PC provided by our company.

Product Images

Stage layout example

Mounting of tips

Dispensing operation