EDR-VS8/VS10|Pipetting System

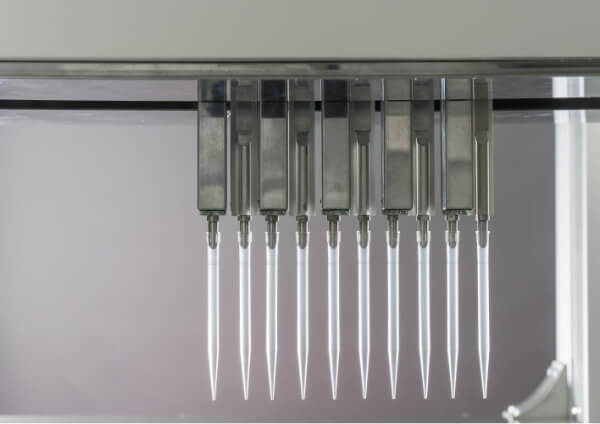

Pipetting System EDR-VS8/VS10

Multichannel Variable Pitch Sampling System

Specimen sampling/Reagent dispensing

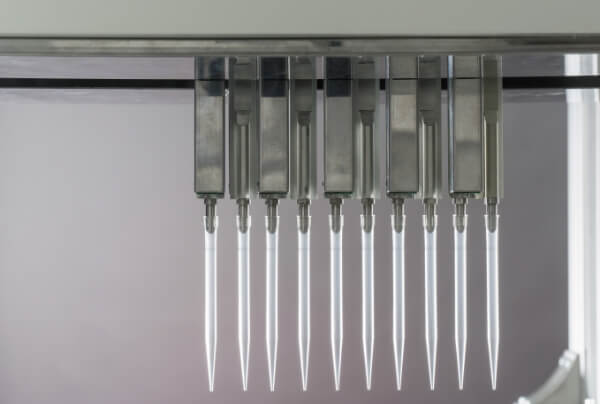

- Choose from 8 and 10-ch models to meet your needs.

- This model enables various layouts of plates, tube racks and containers suitable for your application.

- You can also lay out a temperature control unit, bar code reader and other devices.

- Dispensing head system with a small air gap for high-precision dispensing (10 - 1200 μl).

- Sensors enable real-time tip mounting checks, liquid level detection, and detection of suction abnormalities.

- A processing speed of 1000 samples per hour (8-ch model)

Areas to Which the System Has Been Applied

Cells

Clinical testing

Food inspection

Diagnostic reagent manufacturing

| Dispensing system | 8-ch/10-ch independent cylinder system |

|---|---|

| Dispensing volume | 10 - 1200 µL |

| Compatible plates | Various 96 micro-well plates, deep well plates, PCR plates 1.5 mL/2.0 mL microtubes, blood collection tubes, centrifuge tubes, etc. |

| Dispensing precision | 1000 samples per hour (8-ch model) |

| Accuracy | 100μl±2µL |

| Pitch variable range | 9~25mm |

| Power supply | AC100V 50/60Hz |

| Control | Dedicated PC software (VS) |

| Dimensions | W1400mm×D900mm×H1200mm |

| Weight | about 190 kg |

(1) Complete idle suction (When there is no liquid from the beginning), (2) Half idle suction (When there is a shortage of liquid), (3) Clogging detection (When the tips are clogged),

Other cases such as where there are no tips, and cases where jamming (a collision) occurs.

(Carbon tips are not used.){3}

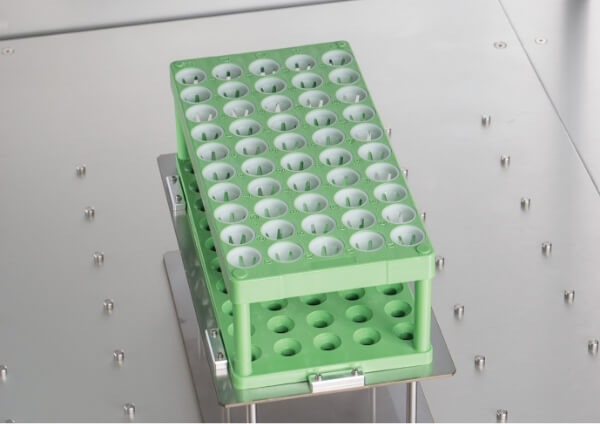

Product Images

Tip racks/Tip disposal unit

An arbitrary number of 1200 μl tips can be set.

Used tips are removed with a disposal unit and disposed of outside the work area.

Flexible layout of tip racks.

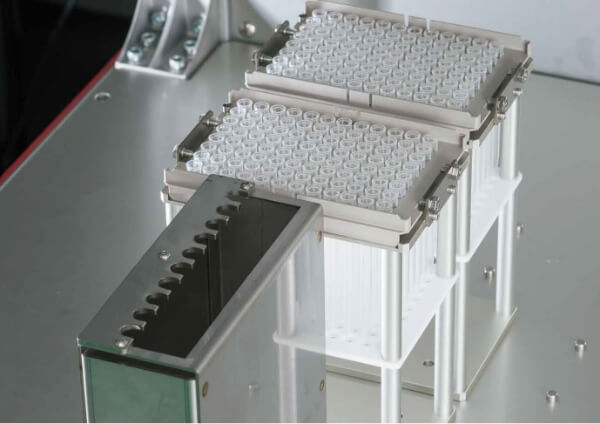

Work area

This work area can provide 24 stages for standard microplate stands.

Plate racks can be placed vertically and horizontally in accordance with the dispensing direction.

Movement patterns can be by visually representing the layout of the work area.

The work area allows the installation of various units and optional equipment in it.

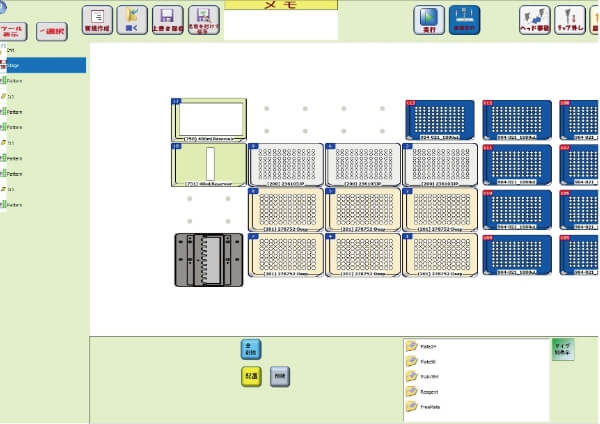

Software

Dedicated software is used to control operations from a PC.

Movement patterns can be by visually representing the layout of the work area.

Registering and using container information such as plates automatically calculates the height of head movement and access, enabling safe and smooth movement.

The software can handle various qualities of liquid and reproduce dispensing operations close to manual operations.

A screen layout can also be created to suits your needs. (Options)

Service outlets and external communication ports

Service outlets (can be turned on or off from the software) and external communication ports are provided on the side of the main unit.

10-channel variable pitch (1)

10-channel variable pitch (2)

10-channel variable pitch (3)

Plates placed lengthwise

Plates placed crosswise

Aloka rack